From small through medium ending up on big capacity concrete batching plants, Prometal presents most efficient way of concrete production with great results of high quality concrete. Our clients can choose between 15 cubic meters per hour to 120 cubic meters per hour capacity concrete batching plants. Long lasting structures and stable design provides our customers long term profitable investment with no regrets.

Electric installation of concrete batching plant includes all electrical connections of voltage controlling and part for measuring of the plant. All installations and safety devices are made by EC regulations, protection IP 67 no matter of operation type manual or automatic. Controlling of whole plant is done by PLC Siemens controller which gives returning connections of the system which are part of safety demands.

Aggregate hopper is designed and manufactured to operate under heavy working conditions for a long time. There are 2 electro-pneumatically controlled discharge gates, which provide easiness and choice in the discharge together with suitable elevation. Aggregates are weighed by S type load cells.

Large variety of cement silo sizes provides to our customers right equipment that can suit small to big production of concrete. Cement screw conveyors are manufactured by WAM Italy, following that complete equipment is equipped with WAM Group equipment.

To combine and tailor concrete batching plants our clients can choose between:

Concrete mixer (turbine, planetary or twin-shaft) with or without movable skip

Platform steel structure (made and designed by customer needs)

Mixer feeding conveyor

Aggregate hoppers with weighing belt conveyor adapted to size of concrete batching plant

Cement weighing scale

Water weighing scale

Additive system for dosing chemical additives

Cement silos with following equipment and cement screw conveyors

Electric installations and controlling of batching plant with PLC Siemens controller

Insulated control room

Insulation construction from sandwich panels with sub construction for winter execution

Many more equipment per customers demand.

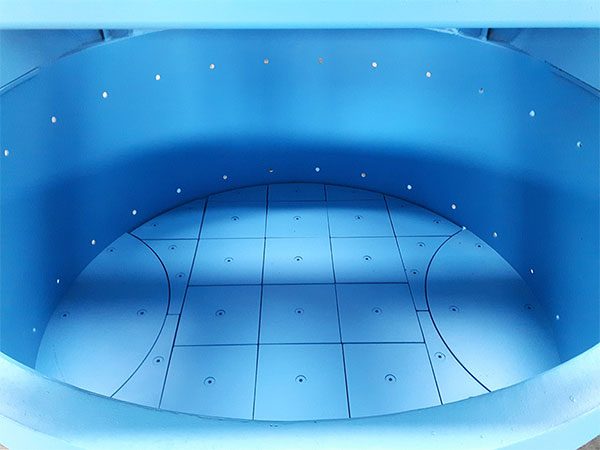

Planetary Type Mixer has three arms per star and can have one or even two stars on bigger model size. This system generates counter-current flow of the batch materials, that type of mixing action

results in more efficient and aggressive shuffling of aggregates, which provides shorter cycle times as well as less wear. Identical floor tiles are low cost and can be individually replaced.

The planetary (or counter current) design has from one to two mixing stars that rotate while in the same time they rotate around a central point, allowing each arm to cover the whole mixer floor in a number of revolutions. This powerful mixing action is both fast and thorough, resulting in a mixing time, after water is added, of 30 seconds or less for most types of concrete. The result is greater throughput, leaving more concrete per hour for the same size plant, as well as better consistency and greater strength or, on the other hand saving on cement.

Prometal mixers provide wide range of opportunities to its clients for upgrading their products with accessories as skip hoists, water weighing systems, cement weigh hoppers and dust reducing airbags, high pressure wash systems, accelerated discharge blades and multiple discharge doors. Customers can modify and choose equipment that can satisfy their needs as every product is customizable so it can fit to different needs.

Turbine Type Mixer comes in 8 different sizes from 175-1500 litre output. Tank walls and floor are lined in wear resistant steel plates. Rotating drive system with spring shock absorbers protects drive gearbox in case of mix blades hit any obstruction. Mixer has features like robust and space-saving drive system, multiple discharge gates, easy access to areas inside of mixer and low overall height.

The main advantages and features of TM series of mixers:

High speed turbine concrete mixer, like the others in the family has been carefully designed and perfected over many years to be fast, rugged and reliable. The TM turbine mixer is a world class performer in the production of both wet and dry cast concrete.

The TM’s mixing action comes from the rotating blades, which are scientifically designed to push the material from the inside to the outside of the chamber and back again, whilst lifting and folding it, mixing the concrete fully in a few revolutions.

As previously mentioned the TM’s mixing arms are suspended from spring-action mounts, allowing them to ride up and over any possible obstructions without damage. The large, cool running epicyclical reduction gear is direct driven so there is no belts to wear and break.

This type of mixer does not require extra cleanout mechanisms so cleanout can be thorough, fast and easy.

Turbine type of mixers has best cost to profit ratio.